Automation is really a defining function of CNC machining, revolutionizing the manufacturing landscape. CNC machines function under the steerage of Personal computer plans, allowing for for specific control and automation of the complete machining process.

As a leading service provider of precision machining services for that aerospace sector, Exam Products by SCHENCK excels in manufacturing safety-crucial rotating components making use of complicated aerospace alloys.

Personalised Drugs: CNC machining will Enjoy an ever-increasing function inside the production of customized medical gadgets customized to personal affected individual desires.

With over one hundred fifty years of knowledge in turning, DMG MORI presents complete technological knowledge, reflected in all-around 20 different number of CNC lathes: To be a machine tool maker, we protect a variety of applications, from adaptable universal lathes and innovative switch-mill centers (Flip & Mill) to highly affordable production turning.

Within the realm of automation, CNC machining performs an important job in making specialised machinery, conveyor systems, and intricate parts for automated production lines.

For example, AI can forecast tool wear and regulate cutting speeds to stop tool failure, reducing downtime and extending the lifespan of costly equipment.

As we’ve explored high precision CNC lathes as well as their pivotal purpose in modern-day manufacturing, it’s obvious that Read more the choice of equipment can fundamentally shape the quality, efficiency, and innovation of one's production processes.

Multiaxis machining refers to the capability of a CNC machine to function alongside four or more axes, including levels of complexity and precision on the machining process. In contrast to common lathes that function together just one aircraft, multiaxis machines can rotate and pivot, letting for intricate designs that were Earlier unattainable or highly time-consuming.

However, they are doing feature their list of challenges, including the Preliminary financial commitment and the necessity for expert operators.

These machines are designed to previous for many years, providing unparalleled precision that’s crucial in industries like aerospace and medical product manufacturing.

In summary, the breakthroughs in CNC lathe technology, highlighted by multiaxis machining and numerical control, have considerably expanded the probabilities for precision machining. With all the addition of live tooling, now’s high precision CNC lathes tend to be more multipurpose and successful than previously before, able of producing complex metal parts with unparalleled accuracy.

Tolerance grades are A different critical time period. They’re similar to the rulebook for precision, defining just how much deviation from the ideal measurement is acceptable. From the high precision globe, we purpose to the tightest tolerances, wherever deviations are scarcely measurable.

A strong main spindle makes sure that all models present the ideal speed as well as the required torque. Length involving centers, center top or swing diameter – The variability of models gives acceptable sizes for every application.

In the event you’re in the market for a high precision CNC lathe, aiming for machines that marry top rated-tier accuracy with reliability is crucial. Appear no even further for just a concise rundown:

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Destiny’s Child Then & Now!

Destiny’s Child Then & Now! Freddie Prinze Jr. Then & Now!

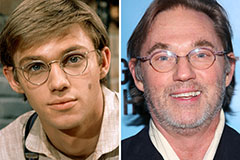

Freddie Prinze Jr. Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!